Calibration

Sensor calibration is an essential element of a reliable Life Safety System. Hazardous material sensors drift over time regardless of the technologies involved. At Ino-tek, we work with sensors from virtually every manufacturer, utilizing every technology. Routine calibration will keep your systems operating at peak efficiency and effectiveness.

Regular calibration adjustments, including filter replacements, bump checks and zero-gas (when required) will help keep your system running at optimum performance. By calibrating regularly, you’re minimizing costly process downtime and false positive alarms due to normal gas detection sensor drift.

Certification

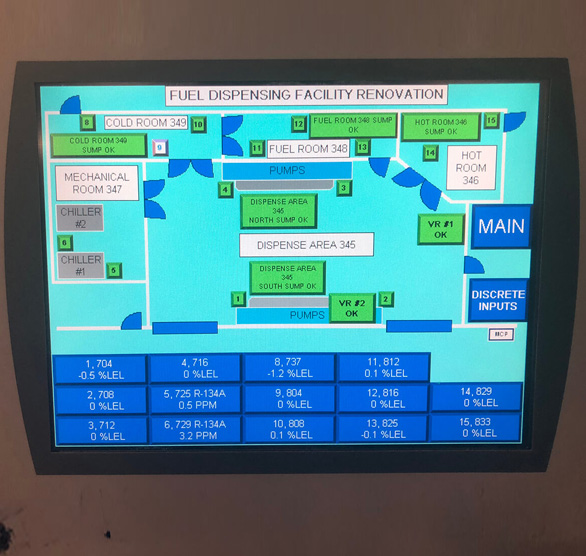

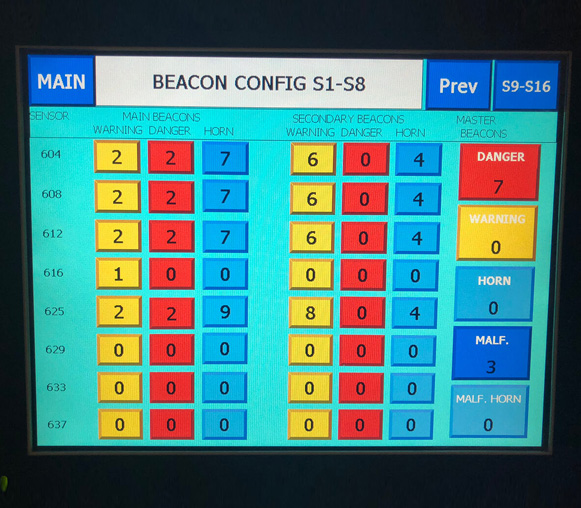

Annual “System Certification” keeps you in compliance with state laws. Certification includes verification of all Hazardous Material Emergency Alarm System logic, battery backup operation in accordance with NFPA 72, verification of all exhaust and purge ventilation monitoring and interlocks, verification of system shutdown interlocks, pump or isolation valves and manual emergency pushbuttons as well as interlocks to remote 24-hour monitoring stations, visual and audible alarms.

Annual Certification reports are provided to the local municipal fire authority or AHJ (Authority Having Jurisdiction) to verify the annual operational audit has been performed and the system is fully operational.

Repair

All gas detection components require periodic replacement over time. Different sensor technologies have different life spans and different maintenance requirements. Hostile environmental conditions can accelerate maintenance requirements.

Because Ino-Tek works with virtually all brands of equipment, our troubleshooting capabilities are second to none! We know what parts break down and can even contribute our insights into a progressive maintenance program to ensure customer facilities maximize throughput through a scheduled replacement and maintenance program.

Update

Evolving customer requirements and aging safety technology can create gaps in the critical Life Safety and Hazardous Material Emergency Alarms System safety envelope. Ino-Tek can help! We can evaluate your existing system components and recommend when to re-task and when to replace. Sensor locations can take advantage of the newest Ino-Tek remote sample draw designs to minimize ongoing calibration costs and maximize facility uptime.

Have you added to new processes or research requirements?

Our Service Capabilities

Every day, our fleet of service trucks and certified field technicians are working to solve customer problems around Hazardous Materials and to keep Your People Safe! Life Safety Systems, including Gas Detection, Leak Detection, and even Explosive Dust, require highly-trained professionals with the smarts to get the job done right.

For existing customers and installations, we maintain complete project details including hazards at the time of installation, as-built drawings and all software programming.

For new customers and new job sites, we conduct an inspection of the facility and the systems installed. We’ll make certain we understand why the system was installed and how it was supposed to function. Then, we’ll prepare a quote to restore your system to functional status.

For spaces that have new functionality, a Hazardous Material Opinion and Report may be the appropriate first step. This is a required document for Building and Fire Officials but can be especially helpful to owners because it outlines the hazardous materials present and highlights the requirements for Code Compliance. The report tells you about the hazards, the protections the Building and Fire Codes require and whether the space is or will be appropriate for the intended use. It reviews the processes and the hazards (both present and expected) – their quantities (both in use and in storage, open and closed), and the temperatures and pressures involved. The classification of materials is based upon Section 307.1 and Section 414.1.3 of the International Building Code as adopted by all the states. This is the applicable system of classification for Building and Fire Code purposes and is separate from DOT and other standards that may appear in various Safety Data Sheets provided by suppliers. The report presents a “snapshot” of the material quantities and the implications those quantities have for area classification inside your facility as of a specific point in time.

Ino-Tek supports virtually all brands of hardware so there is never a need to fly in a factory service technician – which usually involves high cost and significant delay. We support our field technicians with in-house programming capability and can even reprogram selected systems remotely.

As required by State Building Codes, (IBC), The International Fire Code (IFC) and the National Fire Protection Association (NFPA), calibration, service, repairs and annual certifications of Life Safety Systems may only be performed by specially trained technicians.

The Ino-Tek Service team is with you every step of the way!

Need Maintenance on an

Existing Gas or Leak Detection System?

Schedule a Field Service Engineer who will inspect your facility and make sure it meets all compliance requirements.