Considered Motor Vehicle Areas, Auto Repair facilities have different Gas Detection requirements than Parking Garages (which have their own prescriptive language) according to the International Building and Fire Codes (adopted by every State in the United States). The safety requirements increase as the level of maintenance performed increases. For a simple oil change facility, with adequate ventilation, there may be no requirement for gas and leak detection. For a facility with more extensive operations – including the removal of gas tanks and extensive work on fuel management systems, both Gas Detection and Leak Detection may be required.

The current mix of vehicles on our roads is almost exclusively fueled by gasoline and diesel. In addition to the hazards generated by leaking fuel systems, operating a vehicle in a closed space can quickly generate dangerous levels of Carbon Monoxide (CO) and Nitrogen Dioxide (NO2) – the common byproducts of vehicle exhaust.

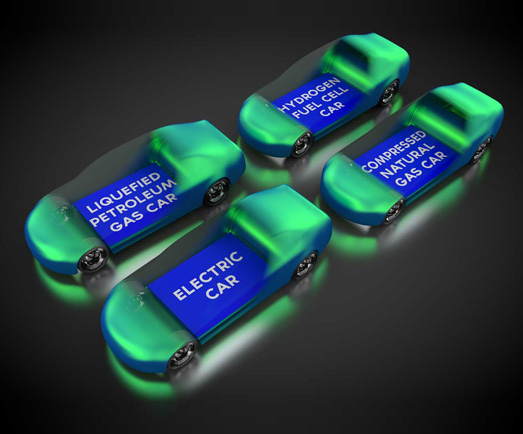

One new hazard to hit the automotive repair facility is the growing adoption of hybrid vehicles – adding the potential for releases of both hydrogen and hydrogen sulfide gases as well as acid leaks from damaged or punctured batteries. Other emerging technologies include Compressed Natural Gas (CNG) and Propane-fueled vehicles – technologies under development for personal vehicles but which remain concentrated almost exclusively to truck and transit fleets currently.

Another emerging vehicle fuel hazard for Auto Repair Garages will be Hydrogen – the common energy source for fuel cells. Odorless and colorless, with a density far lighter than air, leaking hydrogen could accumulate in ceiling areas where wiring and other electrical components are inappropriate for a flammable gas buildup.

Ino-Tek has worked with virtually all major automakers and their suppliers as their testing and maintenance facilities are renovated to reflect the changing – and expanding – hazard landscape.

A Hazardous Material Emergency Alarm System / Gas Detection System can actually reduce operating expense!

Interested in knowing more about an auto garage ventilation system?

Talk to one of our Field Service Engineers to make sure it meets all compliance requirements.